Coil handling poses a unique challenge, in that there are just as many options for lifting equipment as there are variations in the requirements. This post will describe some of Bradley Lifting’s offerings for coil handling equipment, to help you make an informed decision based on your needs.

Motorized Horizontal Coil Lifters

Telescoping

Motorized Telescoping Coil Lifters are a highly flexible option for handling coils in the axis horizontal position. The telescoping legs allow the lifter to handle a wide range of coil diameters and widths while also maintaining low headroom.

The legs are telescoped “in and out” by a motor with brake directly coupled to a worm gear reducer with torque limiter, chain drive and final rack and pinion. Dual sliding members are used for better support of the telescoping legs. Replaceable brass wear plates are provided within the frame of the unit, to increase the service life of the leg members.

These units can be provided with a variety of options to suit the needs of your application. Motorized rotators, flip-up lifting feet, hold-down arms for un-banded coils, and digital weighing systems are just a few of the available features.

Coil protection features, such as coil edge contact plates and load presence indicators can be added to ensure the safety of both personnel and products. These features can also be integrated into crane automation systems, to allow the lifter to function in automated facilities.

Parallelogram

Parallelogram Coil Lifters are another motorized lifter type designed for coils in the axis horizontal position. The linkage mechanism is well suited for coil storage areas with narrow aisles, but it does require additional headroom to operate when compared to a Telescoping Coil Lifter.

The legs are driven “in-and out” by a motor with brake, chain drive, worm gear reducer with torque limiter, chain drive and final crank linkage.

Like Telescoping Coil Lifters, there are a variety of optional features that can be added to suit your application. Powered rotation, retractable feet, and a multitude of additional safety devices are just some of the available options.

Vertical Internal Coil Lifter

Coils in the axis vertical position can be handled by an Internal Coil Lifter. Depending on the overall width, this unit can also handle a stack of coils.

Similar to the Telescoping Coil Lifter, the legs are driven “in and out” by a motor with brake directly coupled to a worm gear reducer with torque limiter, chain drive and final rack and pinion. These units can also be provided with a handwheel, to allow for manual operation instead of powered.

The coil is lifted via feet which engage under the coil wall. For this unit type to function properly, coils must be stored on dunnage that provides space for the lifting feet.

This style of lifter can be provided with many of the optional features available for Telescoping Coil Lifters, such as coil edge contact plates, load presence indicators, and motorized rotators.

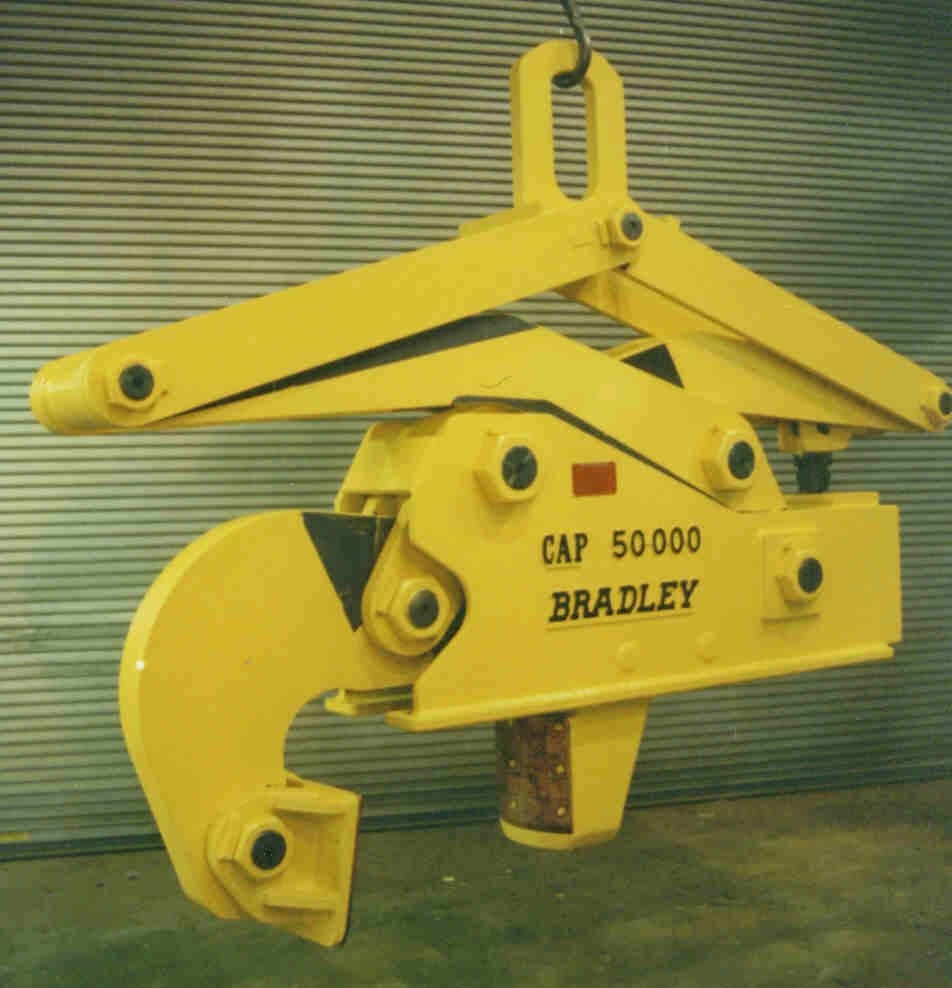

Vertical Coil Tong

For coils positioned with the axis vertical (“eye to the sky”) and the underside of the coil is not accessible, a vertical axis coil tong is the best handling solution. These tongs are designed to handle a specific range of coil sizes.

Depending on your needs, the tong can be designed for either single-rim grip or double-rim grip as well as single or double coil handling.

“Single-Rim” grip means that the coil is gripped on one side between the ID and OD of the coil. This is suitable for heavy gauge coils where the ID and OD are consistent within a limited range.

“Double-Rim” grip is more secure, since the tong grips on both sides of the coil, and is more suitable for delicate, thinner gauge strip. Double-Rim tongs are also more tolerant of variation of the coil ID and OD.

Like the rest of our automatic tongs, these units offer virtually “hands-free” operation. The latch is designed to hold the legs open and allow them to close and grip the load with vertical hook motion.

C-Hooks

Heavy-Duty C-Hooks are a simple and effective solution for your coil handling needs. Our C-Hooks feature a frame cut from single, alloy steel plate and are designed for a 24/7 production environment.

C-Hooks are an excellent solution when you need to stack coils or slit coils closely together, end-to-end, or when access to the coil I.D. is restricted to one side.

C-Hooks can be provided with additional features such urethane bumpers, low-headroom designs, and motorized rotation.

The large variety of options for coil handing equipment means that there is a solution that will suit almost any requirement and request. Interested in learning more, or have a need for a new Coil Lifter? Click Here to contact us and one of our Applications Engineers will be glad to answer any of your questions.

Horizontal Ingot Handling Equipment

Horizontal Ingot Handling Equipment