Ingot Lifters

Bradley Lifting offers an extensive range of solutions for handling of Aluminum and Steel Ingots. Vertical drop casting, continuous casting, ingot storage, ingot scalping, and furnace loading are just some of the many applications where we have provided our highest quality lifting equipment. Whether mechanical or Motorized, our unique, custom designs offer an unparalleled level of safety and performance. Contact us to discuss your application today!

Horizontal Ingot Tongs

Horizontal Ingot Tongs from Bradley Lifting are rugged, mill-duty lifting devices suited for continuous operations where reliability and up-time are critical. Bradley Lifting offers Horizontal Ingot Tongs with a full mechanical design where the unit is held open by a heavy-duty automatic latching mechanism. Horizontal Ingot Tongs with automatic latches are generally used for single ingot handling. Horizontal Ingot Tongs are a great solution if you are unable to bring power to the unit from your crane or if your application includes a small to medium range of ingot widths. Our mechanical tongs can also be configured for high temperature ingot handling (> 1000°F).

For multiple ingot handling, Hoist Operated or Motorized Horizontal Ingot Tongs are available. Hoist operated tongs can use the auxiliary hoist to control the opening and closing of the tong while suspended from the main hoist. Motorized Horizontal Ingot Tongs utilize an electric motor to open and close the tong (self-contained) for selective pick-and-place of either a single or multiple ingots from a stack.

Vertical Ingot Tongs

One of the most common operations when lifting an ingot is “down-ending”: the lift starts with the ingot vertical, but then rotated to a horizontal position. Bradley Vertical Ingot Tongs are ideal for use in this application because of their long track record of safety and performance. Bradley Lifting has hundreds of down-ending grabs in operation around the world. Each Ingot Tong can be customized to meet your specific application requirements.

Hydraulic locking devices are available to help to keep the tong legs closed on the load in the event that the bottom of the ingot accidentally contacts the floor, for the ultimate in handling safety. The device is entirely self-contained, and only requires that the operator release the lock when the ingot is at rest in the horizontal position, to reset the tong.

Motorized Vertical Ingot Grabs

Bradley Motorized Vertical Ingot Grabs are unmatched in safety and performance. Our unique design is proven in Aluminum Casthouses and ESR casting operations around the world. Redundant locking systems ensure that the grip is not compromised when laying down ingots and provides the utmost productivity for stripping vertical casting pits. Powered rotation, load detecting systems, positioning systems, feedback indicators and other features are also available. Contact a Bradley Applications Engineer to discuss how we can configure a grab to improve safety and increase productivity for your casting operations today!

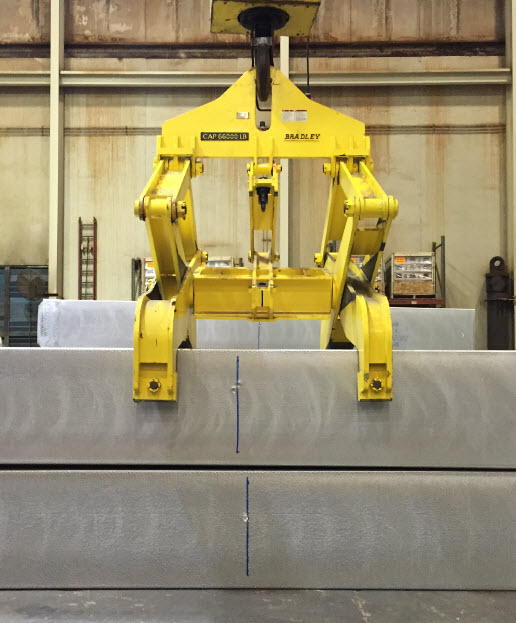

Motorized Horizontal Ingot Grabs

Bradley Motorized Horizontal Ingot Grabs are rugged, mill-duty lifting devices suited for continuous operations where safety, efficiency, reliability and up-time are critical. Our exclusive design offers the maximum range of ingot handling in a compact, robust design. These grabs are proven solutions utilized by premier metal producers around the globe. Our Horizontal Ingot Grabs are custom-designed to suit your specific application. Some example applications include ingot storage areas, ingot scalpers, casthouses, and rolling mills. In addition to many safety features available, our grabs can also be outfitted with the latest sensor technology to provide seamless integration with your automated material handling systems.

Asked & Answered

Q: How do I choose between a motorized or mechanical device?

A: If power is not available at the hook, a mechanical device is the right choice. Motorized devices offer improved safety features and performance and usually require less headroom to operate. Motorized lifters also handle a greater range of sizes with one device.

Q: What is a “Hydraulic Locking Device”, and why would I need it?

A: When picking ingots vertically (such as with a vertical drop casting system) and laying the ingot horizontally (downending), the potential exists to contact the ingot with the floor or other fixed surface which can compromise the mechanical grip of the lifter. The “Hydraulic Locking Device” help to prevent this loss of mechanical grip, thereby improving the safety of the downending operation.

Q: Are there any limits to the size of Ingots I can handle?

A: All of our lifters are custom designed. Call us to discuss your application with a Bradley Engineer. Through our extensive experience with these applications, chances are we’ve provided solutions similar to your needs.

GET ANSWERS